BR0.50 Series Plate Heat Exhanger

- Category:Heat Exchanger

- Material:SUS304, SUS316L

- Certificate:CCS, BV, ABS, GL,LR, NK

- Packing Details:Standard Export Packaging

- Delivery Time:10 days

- Supply Ability:10 sets/month

- Fob Price:Get Latest Price Now

- Place of Origin:China

Request a Quote

Not what you need, please send your RFQs via Email.

Details

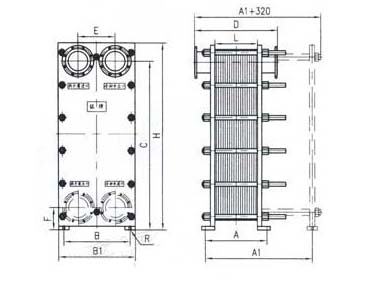

|

Serial Number |

Transfer Area(m2) |

Plate number |

L(mm) | D | A | A1 | Weight(kg) |

| 1 | 70 | 71 | 270 | 730 | 490 | 995 | 2318 |

| 2 | 80 | 81 | 308 | 770 | 528 | 1055 | 2412 |

| 3 | 90 | 91 | 342 | 802 | 562 | 1130 | 2505 |

| 4 | 100 | 101 | 384 | 845 | 604 | 1195 | 2600 |

| 5 | 110 | 111 | 418 | 880 | 638 | 1270 | 2690 |

| 6 | 120 | 121 | 460 | 920 | 680 | 1330 | 2787 |

| 7 | 140 | 141 | 536 | 995 | 756 | 1470 | 2974 |

| 8 | 150 | 151 | 374 | 1035 | 794 | 1545 | 3067 |

| 9 | 160 | 161 | 612 | 1070 | 832 | 1605 | 3160 |

| 10 | 180 | 181 | 688 | 1150 | 908 | 1745 | 3348 |

| 11 | 200 | 201 | 764 | 1225 | 984 | 1885 | 3535 |

| 12 | 210 | 211 | 802 | 1260 | 1022 | 1955 | 3628 |

| 13 | 220 | 221 | 840 | 1300 | 1060 | 2020 | 3722 |

| 14 | 230 | 231 | 878 | 1340 | 1098 | 2095 | 3815 |

1. The plate heat exchanger's brief introduction:

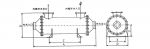

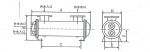

Plate heat exchanger is composed of framework, heat transfer plate set and clamping bolt and other major parts.

Framework includes a fixed pressure plate and a pressure plate, on the guide rod and the guide rod bearing, a pillar at the other '.Compressed into corrugated plate hanging on the guide bar in between the two panels, mobile activity compaction pressure plate to plate group, with a set of clamping screw will be fixed pressure plate and the activity of compacting powder compact to a certain size.Two kinds of medium by the fixed (or activities) on the pressure plate flange holes into the composed of corrugated plate of each channel, after the heat exchange medium again by fixed (or activities) on the pressure plate flange hole.With constant pressure plate, pressure plate, pillars and guide bar are low carbon steel.Considering the various requirements of the users, framework design has a variety of forms, mainly has double support frame type and common floor, etc., can also according to the requirements of the user changes the framework model.

Heat transfer plate is one of the core parts of plate heat exchanger.Corrugated plate through a pressure molding, design reasonable ripple increases the effective heat transfer area of plate and make the flow ripple through the turbulence formation, to strengthen the heat transfer process.Assembly ripple and ripple cross into a lot of contact resistance points, greatly improving the plate stiffness, so can bear high pressure.Every board piece as a heat transfer surface, under the action of the seal, both sides of the plate respectively by cold and hot medium, heat transfer.Plate with four away L of liquid distribution, away L and plate around with sealing gasket, restrict the flow of medium in the plate group, the plate form parallel channels, flows through the inside of the two kinds of medium, make the best effect of heat transfer in the direction of the flow, in order to adapt to a variety of strong corrosion medium, corrugated plate materials are: pure titanium TAl, used in seawater or other corrosive medium;A variety of stainless steel, with j = fresh water, drinking water, oil and other corrosive medium.

Framework includes a fixed pressure plate and a pressure plate, on the guide rod and the guide rod bearing, a pillar at the other '.Compressed into corrugated plate hanging on the guide bar in between the two panels, mobile activity compaction pressure plate to plate group, with a set of clamping screw will be fixed pressure plate and the activity of compacting powder compact to a certain size.Two kinds of medium by the fixed (or activities) on the pressure plate flange holes into the composed of corrugated plate of each channel, after the heat exchange medium again by fixed (or activities) on the pressure plate flange hole.With constant pressure plate, pressure plate, pillars and guide bar are low carbon steel.Considering the various requirements of the users, framework design has a variety of forms, mainly has double support frame type and common floor, etc., can also according to the requirements of the user changes the framework model.

Heat transfer plate is one of the core parts of plate heat exchanger.Corrugated plate through a pressure molding, design reasonable ripple increases the effective heat transfer area of plate and make the flow ripple through the turbulence formation, to strengthen the heat transfer process.Assembly ripple and ripple cross into a lot of contact resistance points, greatly improving the plate stiffness, so can bear high pressure.Every board piece as a heat transfer surface, under the action of the seal, both sides of the plate respectively by cold and hot medium, heat transfer.Plate with four away L of liquid distribution, away L and plate around with sealing gasket, restrict the flow of medium in the plate group, the plate form parallel channels, flows through the inside of the two kinds of medium, make the best effect of heat transfer in the direction of the flow, in order to adapt to a variety of strong corrosion medium, corrugated plate materials are: pure titanium TAl, used in seawater or other corrosive medium;A variety of stainless steel, with j = fresh water, drinking water, oil and other corrosive medium.

On corrugated plate seal groove is equipped with sealing gasket, sealing gasket design into double sealing structure, and a signal.When the medium such as from the first line of the seal leak, away from the signal emission equipment, L can be found that the problem be solved as early as possible, will not result in a mixture of two kinds of medium.Sealing gasket can be selected according to different fluid and operating temperature of different analysing.

2. The plate material:

* adopts stainless steel SUS304 SUS316L

Clean water, river water, food oil, mineral oil

* industrial pure titanium and titanium alloy Ti tanium palladium and Pal ladium

Water, salt water, saline content

* Hadtelloy hartz Alloy Alloy

Concentrated sulfuric acid, hydrochloric acid, phosphoric acid

* Nickel and Nickel

High temperature and high concentration of caustic soda

Clean water, river water, food oil, mineral oil

* industrial pure titanium and titanium alloy Ti tanium palladium and Pal ladium

Water, salt water, saline content

* Hadtelloy hartz Alloy Alloy

Concentrated sulfuric acid, hydrochloric acid, phosphoric acid

* Nickel and Nickel

High temperature and high concentration of caustic soda

3. The gasket material:

* NBR NBR

Water, sea water, mineral oil, brine is a 15-1 the IO ~ C

* high temperature rubber BNBR -

Mineral oil under high temperature, high temperature water 15-140 - C

* EPDM EPDM

Hot water, steam, acid, alkali, a 25-150 - C

* Fluorine Rubber Viton/Fluorine Rubber

Strong acid, strong alkali, mineral oil, grease and oil, etc. 5-180 - C

* NEOPRENE NEOPRENE

Acid, alkali, mineral oil, low molecular weight fatty hydrocarbon a 35-130 - C

* silicone Rubber Silicon Rubber

High temperature, and some corrosive medium, a 65-200 ℃

Water, sea water, mineral oil, brine is a 15-1 the IO ~ C

* high temperature rubber BNBR -

Mineral oil under high temperature, high temperature water 15-140 - C

* EPDM EPDM

Hot water, steam, acid, alkali, a 25-150 - C

* Fluorine Rubber Viton/Fluorine Rubber

Strong acid, strong alkali, mineral oil, grease and oil, etc. 5-180 - C

* NEOPRENE NEOPRENE

Acid, alkali, mineral oil, low molecular weight fatty hydrocarbon a 35-130 - C

* silicone Rubber Silicon Rubber

High temperature, and some corrosive medium, a 65-200 ℃

4. Advanced plate design concept:

Booster * plate with a new type of diversion area design is a bigger place in plate diversion area velocity using multiplexer channel to increase pressure, equal to the entire board of velocity, greatly improving the plate in the thermal efficiency, reduced the dead Angle, improve the plate scale.

* plate high-strength hanging mouth increase pattern design is designed to hang in the mouth, strengthen the rigidity around the flanging, assembled more neat and beautiful, open the better performance.

* plate middle plate groove design of the inside of the foot board piece continuous corrugated disconnect, coexist of plates I} l added half slot structure, ease plate stress, make the plate more, ABU whole after press forming, small flexible.

* plate interlock design is on board the corners of suppressing special mechanical interlocking structure, to improve the plate assembly easy to string a leak phenomenon, in the process of the plate together more convenient, beautiful.

* plate sealing gaskets are all made from paste buckles form, reduce the operation maintenance cost, easy maintenance.

* plate high-strength hanging mouth increase pattern design is designed to hang in the mouth, strengthen the rigidity around the flanging, assembled more neat and beautiful, open the better performance.

* plate middle plate groove design of the inside of the foot board piece continuous corrugated disconnect, coexist of plates I} l added half slot structure, ease plate stress, make the plate more, ABU whole after press forming, small flexible.

* plate interlock design is on board the corners of suppressing special mechanical interlocking structure, to improve the plate assembly easy to string a leak phenomenon, in the process of the plate together more convenient, beautiful.

* plate sealing gaskets are all made from paste buckles form, reduce the operation maintenance cost, easy maintenance.

5. Plate heat exchanger technology advantages and features:

* high coefficient of heat transfer, heat transfer plate on the circles of special design, can make the fluid flow in low flow velocity under the intense turbulence, turbulence since the net effect and can prevent dirt, make the heat transfer coefficient of the plate heat exchanger tube and shell heat exchanger of 3-5 times.

* economy: under the premise of the same heat, comparison of shell and tube: less investment, low operation cost and maintenance cost is low.

* adjustable: simply increase and decrease plate can meet the needs of process changes.

* compact structure: on the premise of the same heat, take up the space is only half of the tube shell type l / 3

* easy to clean wash maintenance

* economy: under the premise of the same heat, comparison of shell and tube: less investment, low operation cost and maintenance cost is low.

* adjustable: simply increase and decrease plate can meet the needs of process changes.

* compact structure: on the premise of the same heat, take up the space is only half of the tube shell type l / 3

* easy to clean wash maintenance

6. Plate heat exchanger design selection:

(1) the physical parameters of cold and hot medium, such as ph, chlorine content, viscosity, density, thermal conductivity, specific heat, etc.

(2) the import and export of cold and hot medium temperature.

(3) of cold and hot medium flow or one of the traffic.

(4) cold and hot medium pressure loss.

(5) the inherent characteristics of plate heat exchanger, such as plate materials, sealing rubber gasket materials.

(2) the import and export of cold and hot medium temperature.

(3) of cold and hot medium flow or one of the traffic.

(4) cold and hot medium pressure loss.

(5) the inherent characteristics of plate heat exchanger, such as plate materials, sealing rubber gasket materials.

.jpg)

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com