HW/HM Series Double-suction double screw pump

- Category:Screw Pump

- Material:cast iron pump case, Stainless steel pump shaft

- Standards:standard

- Certificate:CCS

- Fob Price:Get Latest Price Now

- Place of Origin:China

Details

HW/HM Series Double-suction double screw pump

General

Double suction double screw pump is mainly made up of driving shaft and driven shaft as well as synchronizer gears installed on them respectively. Each shaft is equipped with a pair of scroll covers having reverse directions of turning. The driving shaft transfers impetus to the driven shaft through synchronizer gear. Therefore there is no metal touch between scroll covers with intermeshing engagement on the driving and driven shafts.

When the pump is running, a sealed chamber with invariable capacity will be formed between the scroll covers with intermeshing engagement on the driving and driven shafts and the pump body or bushing. Fluid media in the pump chamber entering from the suction flange flows evenly to the both ends of screw shaft respectively and comes into the sealed chamber. It is transmitted to the pump body along with the rotation of screw shaft. The both are finally transmitted to the delivery side of the pump after joining together, which achieves the goal of pump delivery.

Features

- Adoption of synchronizer gear drive, no touch between rotating parts, external bearing, independent lubrication, free from influence of media. Therefore, broad range of media conveyance is available, such as fluid media with different properties,including low and high viscosity, lubricity and non-lubricity, etc.

- Pump body with bi-layers structure, media in the pump can be heated and thermal insulated by means of vapors or heat transfer oil, having full and rapid heating.

- The conveyed fluid media doing continual axial motion only in the pump body, having smooth flow discharge without pulsation. It can convey liquid smoothly free from shear, to ensure no changes in the properties and structures of the media.

- HM double suction double screw pump,maximum design pressure as high as 6.3Mpa, integration design in the screw and threaded sleeve enlarging diameter of the shaft, shortening dimensions at axial direction as much as possible and improving rigidity and deflection of the shaft as well as stability and reliability of pump during operating, this kind of configuration and craftwork is the pioneer and advance.

- Independent safety valve structure, users can decide whether to configure it according to practical demands

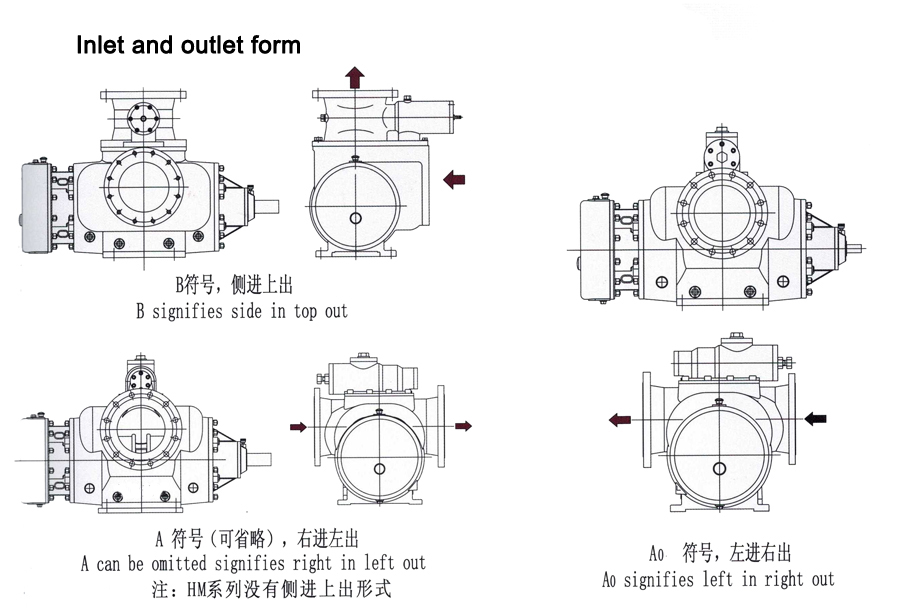

- Different directions for inlet and outlet available

Application scope

- Petroleum industry: Various lubricant, hydraulic oil, fuel oil, residue oil, crude oil and diesel oil

- Chemical engineering industry: Various sour, alkali, salt liquid, resin, glycerin, paraffin wax and other chemical engineering raw materials

- Varnish and industry: Printing ink, various paint, pigment and coating

- Food industry: Alcohol, wet goods, honey, syrup, toothpaste, milk, butter, soy sauce, move plant oil

- Building materials industry: Various heavy oil, residue oil and coal tar

Technique Parameter

HW series double suction double screw pump

- Discharge: 10--800m3/h

- Work pressure:<2.0 Mpa

- Speed: 950rpm/1450rpm

- Temperature: 20--250c

- Viscosity: 2--100000mm2/s

- Suction head<8m

HM series double suction double screw pump

- Discharge:<250m3/h

- Work pressure<6.3Mpa

- Speed: <1450 rpm

- Temperature: 20--180c

- Viscosity: <100000mm2/s

- Suction head<7m

Explanation

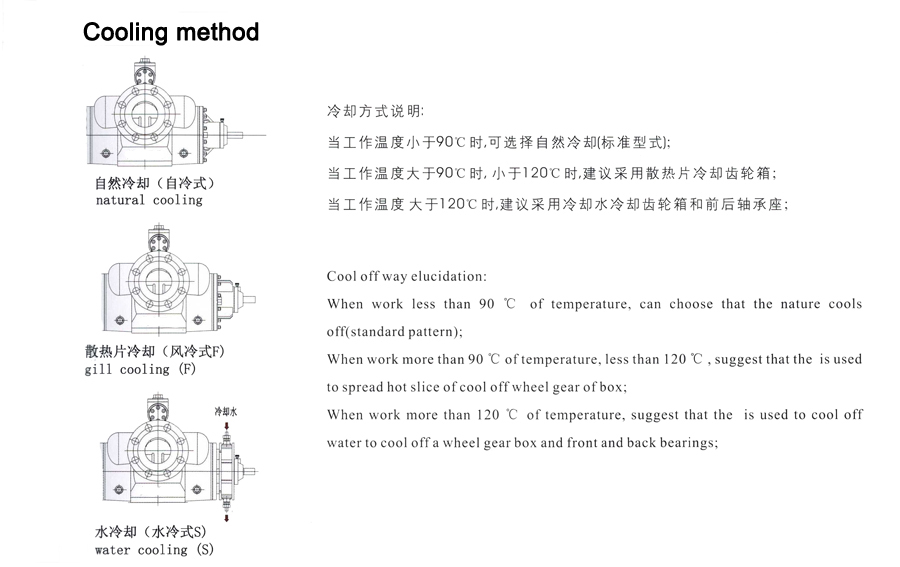

- HW(HM) 100-40 B S

- HW(HM)--Series code

- 100-40--Type code

- B--Type of inlet and outlet

- S--Type of cooling

Inlet and outlet form

Cooling method

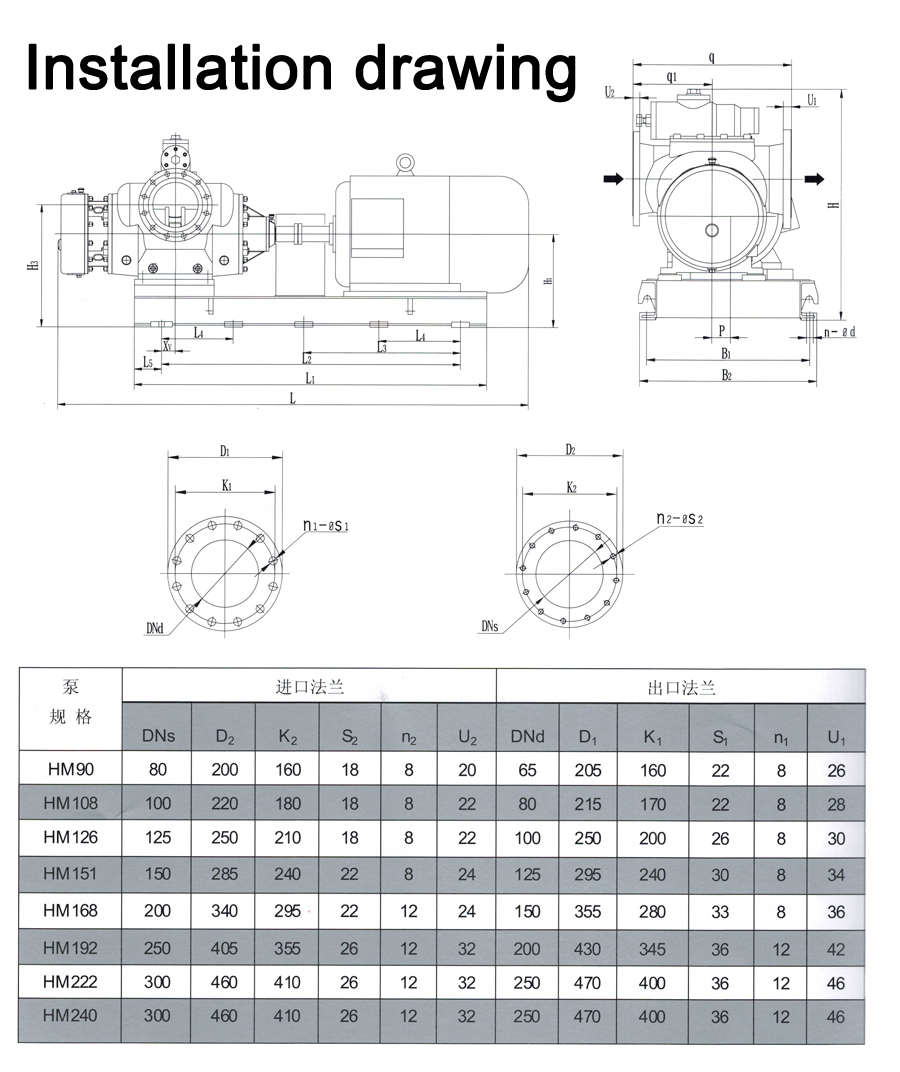

Installation Drawing

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com