Membrane Separator Module Nitrogen Generator System

- Category:Nitrogen Generator System

- Material:Steel

- Certificate:CCS

- Fob Price:Get Latest Price Now

- Place of Origin:China

Details

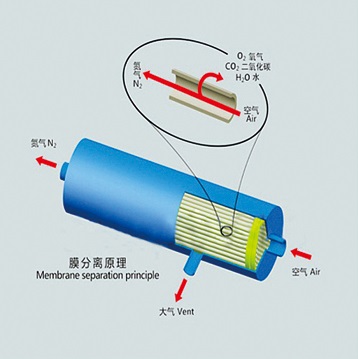

Principle:

Nitrogen separators are made up of many bundles of hollow fiber, and each separator contains thousands of fibers. When two or more than two kinds of mixed air pass through the macromolecule are different, according to the condition, we can distinguish air as “fast air” and “slow air”. When mixed air are effected by different pressure, then fast air such as water hydrogen, oxygen, helium, carbon dioxide will permeate the membrane and are enriched in the infiltration side; Slow air as firedamp, nitrogen, carbon monoxide and argon ect., are enriched in the stagnation side in order to separate the mixed air. When pure compressed air as the air resource, inert gas such as nitrogen will enrich to be the high purity air that can be used in the industry while oxygen in the infiltration side are discharged as exhaust gas.

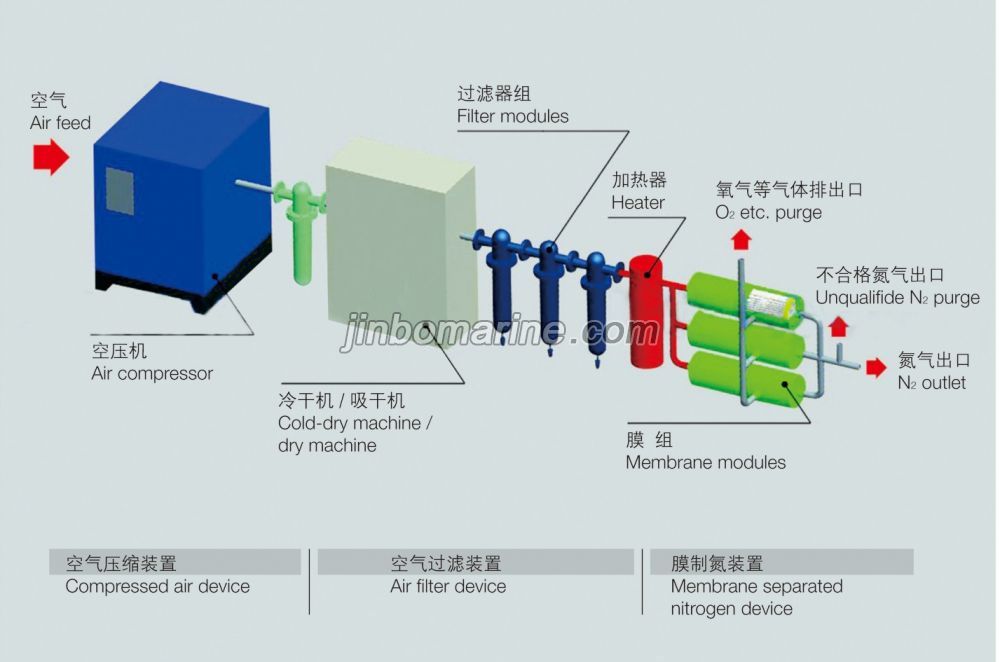

Working Process:

Compressed air supplied by the air compressor enters into air tank, refrigeration dryer and multistage filter containing carbon filter to filtrate particles, oil and water in air. Generally the particle can be filtrated to less than 0.01µm and oil to less than 0.003ppm. The purified air can satisfy requirement of membrane modules totally and be separated there. Nitrogen will enter the user’s section. The qualified nitrogen will enter the next process and the unqualified will be discharged automatically.

Features:

1. The latest technology of normal temperature air separation.

2.High performance membrane module with strict test standard can reduce energy consumption and increase economic benefit for the unser.

3. Compatibilization is simple.

4. Use top-end refrigeration dryer, filter and other assorted equipment to produce high quality nitrogen from air, meanwhile guarantee the service life and operation stability.

5. Low noise, static running to meet the requirements of environmental protection.

6. Easy to operate and produce N2in Short time.

7. Perfect training and service support.

Technology Parameters:

Capacity: 0~3000Nm3/h

Purity: 90%~99.9%(VOL)

Pressure:≤35Mpa

Dew Point:≤40℃

Model No and Specification:

|

Model NO |

Flow Rate (Nm3/h) |

Gas Consumption (Nm3/h) |

Working Pressure (Mpa) |

Size |

||

|

L |

W |

H |

||||

|

YT-CMD100-95 |

100 |

212.77 |

1.0 |

1600 |

250 |

600 |

|

YT-CMD200-95 |

200 |

425.53 |

1.0 |

1600 |

600 |

600 |

|

YT-CMD300-95 |

300 |

638.30 |

1.0 |

1600 |

600 |

800 |

|

YT-CMD400-95 |

400 |

851.06 |

1.0 |

1600 |

600 |

1000 |

|

YT-CMD500-95 |

500 |

1063.83 |

1.0 |

1600 |

600 |

1000 |

|

YT-CMD800-95 |

800 |

1702.13 |

1.0 |

1600 |

600 |

1200 |

|

YT-CMD1000-95 |

1000 |

2127.66 |

1.0 |

1600 |

600 |

1400 |

|

YT-CMD1500-95 |

1500 |

3191.49 |

1.0 |

1600 |

600 |

1700 |

|

YT-CMD1800-95 |

1800 |

3829.79 |

1.0 |

1600 |

600 |

2000 |

|

YT-CMD2000-95 |

2000 |

4255.32 |

1.0 |

1600 |

600 |

2200 |

|

YT-CMD2500-95 |

2500 |

5319.15 |

1.0 |

1600 |

600 |

2500 |

|

YT-CMD3000-95 |

3000 |

6382.98 |

1.0 |

1600 |

600 |

2800 |

Note:

-

The based condition is 1.0Mpa, 20℃temp, 1000mbar atm pressure and 80% relative humidity.

-

O2<5% (VOL)

-

Listed in the table is only a part of the specification, we can properly design according to customer requirements.

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com