PSA Nitrogen Generator System

- Category:Nitrogen Generator System

- Material:Steel

- Certificate:CCS

- Packing Details:Plywood Case

- Fob Price:Get Latest Price Now

- Place of Origin:China

Details

China PSA Nitrogen Generator System:

PSA Nitrogen Generator System is mostly used nitrogen generator system in marine fields, can get the higher nitrogen purity.

Applicable Fields:

Vessel

Oil tank, chemical carrier--- for gas-freeing, inerting and cleaning for cargo tank;

LPG, LNG carrier---for inerting and replacement for cargo tank

Offshore platform

Drilling, completion of oil and gas wells, workover treatment, pipeline cleaning, seal, compression, tank blanketing, pigging and maintenance.

Petrochemical Industry

For nitrogen purging, tank nitrogenization, replacement, leak hunting, protection of flammable gas, tank cleaning.

Principle:

PSA takes advantage of the characteristic of selective adsorption of the CMS. In the cycle period of pressing absorption and depressing desorption, the air separation is achieved in the scrubbers when the compressed air into it alternately, then the high purity N2is produced continuously.

Carbon molecular sieve is a kind of using coal as the main raw material, through grinding, oxidation, molding and carbonization and by the special semi-ellipse treatment processes. The surface and inner is full of microporous bar granular adsorbent that were black. Carbon molecular sieve of O2, N2 separation effect is based on the differences of two kinds of gas dynamics diameter. The diameter of O2 molecular is smaller, so the rate of spread is quicker; the diameter of N2molecule is larger, as a result, the rate of spread is slower.

Working Procedure:

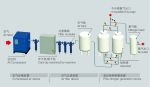

Compressed air device

The air is compressed to a rated pressure with the air compressor.

Air filter devices

Removing the impurities from air with a filter and colddry machine/dry machine to insure the quality of the air source.

PSA nitrogen generation devices

Composed with the air tank, absorbers and nitrogen tank, etc., two absorbers work alternately, one is absorbing to produce nitrogen gas meanwhile the other is desorbing to generate. The nitrogen gas is sent to the buffer tank of low pressure in where purity of nitrogen gas will be tested by the analyzer. The qualified nitrogen gas will be sent to use and the unqualified will be discharged automatically.

Features:

1. The superior performance CMS is used to ensure the stability and longevity of the system.

2. The advanced filling technology and special structure to prevent CMS pulverization to extent the service life.

3. High level of automation, real-time monitoring and recording operating parameter.

4. Kid-mounted integrated design is convenient in transport and stallation.

5. Widely working pressure range (0.4~2.0Mpa).

6.High recovery, reducing air consumption and saving cost.

7. Flexible design can meet different demands of the customers.

8.The scientific structure design, special air flow diffusion apparatus to improve the adsorbed efficiency and avoid the pulverization of sieve from high speed attack caused by airflow.

9. Small scale, large application and low cost.

Technology Parameters:

Capacity: 0~3000Nm3/h

Purity: 90%~99.99%

Pressure:≤35Mpa

Temperature: 20~45℃

Dew point:≤-40℃

Model No and Specification:

|

Model No |

Flow Rate(Nm3/h) |

Gas Consumption(Nm3/h) |

Working Pressure(Mpa) |

Size (mm) |

||

|

L |

W |

H |

||||

|

YT-CPD10-95 |

10 |

24.39 |

0.8 |

1100 |

550 |

941 |

|

YT-CPD30-95 |

30 |

73.18 |

0.8 |

1200 |

600 |

1190 |

|

YT-CPD50-95 |

50 |

121.96 |

0.8 |

1300 |

750 |

1224 |

|

YT-CPD100-95 |

100 |

243.92 |

0.8 |

1600 |

850 |

1354 |

|

YT-CPD150-95 |

150 |

365.88 |

0.8 |

1900 |

1050 |

1428 |

|

YT-CPD200-95 |

200 |

487.84 |

0.8 |

2100 |

1150 |

1472 |

|

YT-CPD250-95 |

250 |

609.8 |

0.8 |

2200 |

1300 |

1546 |

|

YT-CPD300-95 |

300 |

731.76 |

0.8 |

2350 |

1400 |

1674 |

|

YT-CPD400-95 |

400 |

975.68 |

0.8 |

2350 |

1400 |

1874 |

|

YT-CPD500-95 |

500 |

1219.61 |

0.8 |

2350 |

1400 |

2093 |

|

YT-CPD800-95 |

800 |

1951.37 |

0.8 |

2500 |

1600 |

2279 |

|

YT-CPD1000-95 |

1000 |

239.21 |

0.8 |

2500 |

1600 |

2559 |

|

YT-CPD1200-95 |

1200 |

2927.05 |

0.8 |

2500 |

1600 |

2759 |

|

YT-CPD1500-95 |

1500 |

3658.82 |

0.8 |

2500 |

1600 |

2809 |

|

YT-CPD1800-95 |

1800 |

4390.58 |

0.8 |

2500 |

1600 |

2409 |

|

YT-CPD2000-95 |

2000 |

4878.42 |

0.8 |

2500 |

1600 |

2559 |

|

YT-CPD2500-95 |

2500 |

6098.03 |

0.8 |

2500 |

1600 |

2821 |

|

YT-CPD3000-95 |

3000 |

7317.64 |

0.8 |

6000 |

1800 |

2859 |

Note: 1. The based condition is 0.8Mpa, 20℃temp, 1000mbar atm pressure and 80% relative humidity.

2. O2<5% (VOL).

3. Listed in the table is only a part of the specification, we can properly design according to customer requirements.

.png)

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com