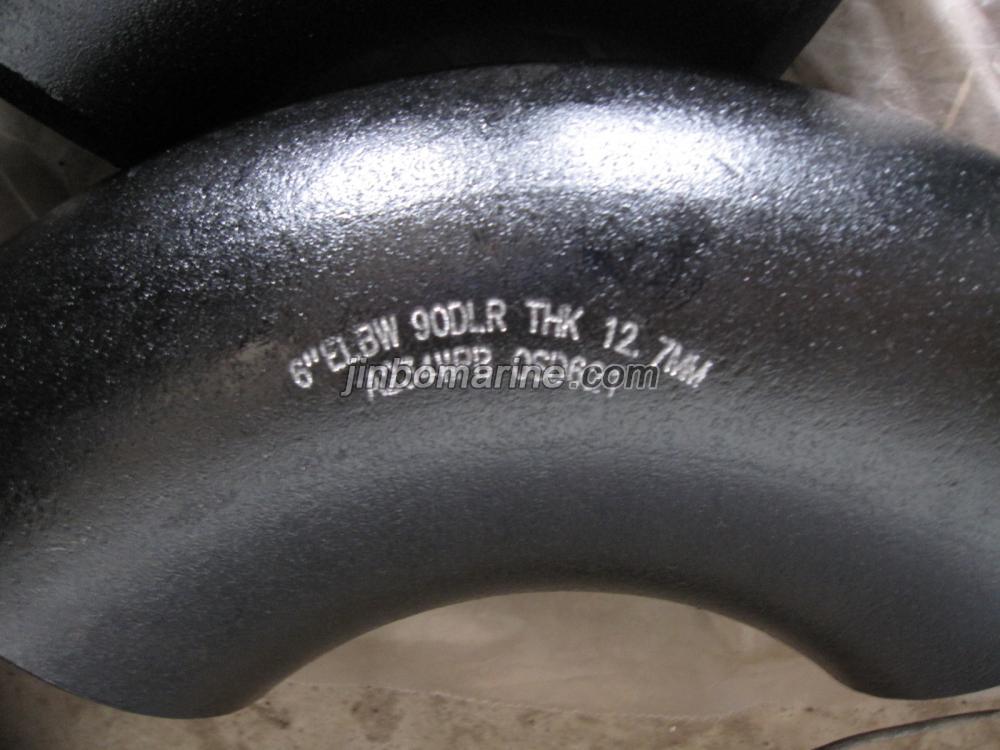

90 Degree Welding Seamless Elbow

- Category:Elbow

- Material:Carbon steel

- Standards:ASTM A234 WPB

- Fob Price:Get Latest Price Now

- Place of Origin:China

Details

Product Description:

Heat induction pipe bending

Induction pipe bending place an induction coil around a pipe. The

coil heats a narrow section of pipe to 800 to 2,200 degrees Fahrenheit,

depending on the material type. Once the proper temperature is reached,

the pipe slowly passes through the coil as the bending force is applied. After

the induction bends are formed, the heated area is cooled by a spray of water

or air.

Creating a precise induction bend requires

extensive induction bending expertise. Compared to cold forming methods,

induction bending minimizes deformation of the material and distortion of

the cross-section even when tight radius bends are required. Pipes formed with

induction pipe bending by Tulsa Tube Bending can be found in power plants,

highway road signs and petroleum pipelines.

ASTM A234 WPB chemical composition

|

Material |

C |

Si |

Mn |

P |

S |

TS(Mpa) |

YS(Mpa) |

E(%) |

AK(J) |

HB |

|

ASTM |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.05 |

≤0.058 |

415-585 |

≥240 |

20 |

--- |

≤197 |

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com