6x19S+IWR Steel Wire Rope Category A

- Category:Steel Wire Rope

- Material:SS Galvanized

- Packing Details:Wooden box

- Fob Price:Get Latest Price Now

- Place of Origin:China

Request a Quote

Not what you need, please send your RFQs via Email.

Details

Wire Rope Definition

a. Wires: steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The tensile forces and to run over sheaves with relatively small diameters.

b. Strand: the strand is a component of wire rope usually consisting of an assembly of wires of appropriate diamsions laid helically in one or more layers around a central element.

c. Core: the core is the central element, of fiber or steel, around which are laid helically the outer strands of wire rope. The core provides proper support for the strands under normal bending and loading conditions.

b. Strand: the strand is a component of wire rope usually consisting of an assembly of wires of appropriate diamsions laid helically in one or more layers around a central element.

c. Core: the core is the central element, of fiber or steel, around which are laid helically the outer strands of wire rope. The core provides proper support for the strands under normal bending and loading conditions.

d. Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands.

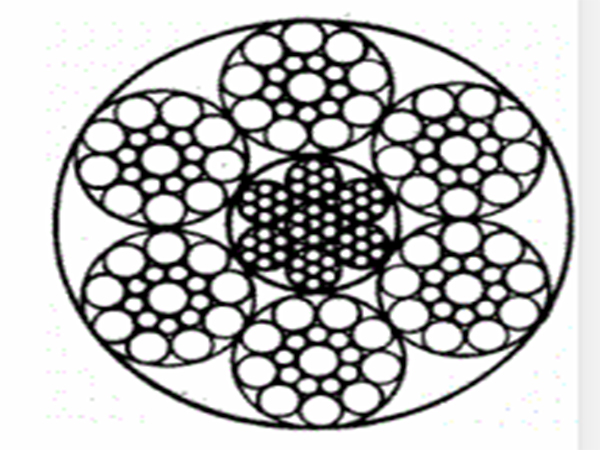

6x19S+IWR Steel Wire Rope Category A Construction

6x19S+IWR Steel Wire Rope Category A Parameter

|

Diameter MM |

Approx.Weight | Minimun Breaking Load of Rope(KN) | |||||

| Kg/100m | 1570Mpa | 1670Mpa | |||||

| NF | SF | IWR | FC | IWR | FC | IWR | |

| 6 | 13.3 | 13 | 14.6.6 | 18.7 | 20.1 | 19.8 | 21.4 |

| 7 | 18.1 | 17.6 | 19.9 | 25.4 | 27.4 | 27 | 29.1 |

| 8 | 23.6 | 23 | 25.9 | 33.2 | 35.8 | 35.3 | 38 |

| 9 | 29.9 | 29.1 | 32.8 | 42 | 45.3 | 44.6 | 48.2 |

| 10 | 36.9 | 36 | 40.6 | 51.8 | 55.9 | 55.1 | 59.5 |

| 11 | 44.6 | 43.5 | 49.1 | 62.7 | 67.6 | 66.7 | 71.9 |

| 12 | 53.1 | 51.8 | 58.4 | 74.6 | 80.5 | 79.4 | 85.6 |

| 13 | 62.3 | 60.8 | 68.5 | 87.6 | 94.5 | 93.1 | 100 |

| 14 | 72.2 | 70.5 | 79.5 | 102 | 110 | 108 | 117 |

| 16 | 94.4 | 92.1 | 104 | 133 | 143 | 141 | 152 |

| 18 | 119 | 177 | 131 | 168 | 181 | 179 | 193 |

| 20 | 147 | 144 | 162 | 207 | 224 | 220 | 238 |

| 22 | 178 | 174 | 196 | 251 | 271 | 267 | 288 |

| 24 | 212 | 207 | 234 | 298 | 322 | 317 | 342 |

| 26 | 249 | 243 | 274 | 350 | 378 | 373 | 402 |

| 28 | 289 | 282 | 318 | 406 | 438 | 432 | 466 |

| 30 | 332 | 324 | 365 | 466 | 503 | 496 | 535 |

| 32 | 377 | 369 | 415 | 531 | 572 | 564 | 609 |

| 34 | 426 | 416 | 469 | 599 | 646 | 637 | 687 |

| 36 | 478 | 466 | 525 | 671 | 724 | 714 | 770 |

| 38 | 532 | 520 | 585 | 748 | 807 | 796 | 858 |

| 40 | 590 | 576 | 649 | 829 | 894 | 882 | 951 |

|

Diameter MM |

Minimun Breaking Load of Rope(KN) | |||||||

| 1870Mpa | 1960Mpa | 2160Mpa | 1770Mpa | |||||

| FC | IWR | FC | IWR | FC | IWR | FC | IWR | |

| 6 | 22.2 | 24 | 23.3 | 25.1 | 25.7 | 27.7 | 21 | 22.7 |

| 7 | 30.2 | 32.6 | 31.7 | 34.2 | 34.9 | 37.7 | 28.6 | 30.9 |

| 8 | 39.5 | 42.6 | 41.4 | 44.6 | 45.6 | 49.2 | 37.4 | 40.3 |

| 9 | 50 | 53.9 | 52.4 | 56.5 | 57.7 | 62.3 | 47.3 | 51 |

| 10 | 61.7 | 66.6 | 64.7 | 69.8 | 71.3 | 76.9 | 58.4 | 63 |

| 11 | 74.7 | 80.6 | 78.3 | 84.4 | 86.2 | 93 | 70.7 | 76.2 |

| 12 | 88.9 | 95.9 | 93.1 | 100 | 103 | 111 | 84.1 | 90.7 |

| 13 | 104 | 113 | 109 | 118 | 120 | 130 | 98.7 | 106 |

| 14 | 121 | 130 | 127 | 137 | 140 | 151 | 114 | 124 |

| 16 | 158 | 170 | 166 | 179 | 182 | 197 | 150 | 161 |

| 18 | 200 | 216 | 210 | 226 | 231 | 249 | 189 | 204 |

| 20 | 247 | 266 | 259 | 279 | 285 | 308 | 234 | 252 |

| 22 | 299 | 322 | 313 | 338 | 345 | 372 | 283 | 305 |

| 24 | 355 | 383 | 373 | 402 | 411 | 443 | 336 | 363 |

| 26 | 417 | 450 | 437 | 472 | 482 | 520 | 395 | 426 |

| 28 | 484 | 522 | 507 | 547 | 559 | 603 | 458 | 494 |

| 30 | 555 | 599 | 582 | 628 | 642 | 692 | 526 | 567 |

| 32 | 632 | 682 | 662 | 718 | 730 | 787 | 598 | 645 |

| 34 | 713 | 770 | 748 | 807 | 824 | 889 | 675 | 728 |

| 36 | 800 | 863 | 838 | 904 | 924 | 997 | 757 | 817 |

| 38 | 891 | 961 | 934 | 1010 | 1030 | 1110 | 843 | 910 |

| 40 | 987 | 1070 | 1030 | 1120 | 1140 | 1230 | 935 | 1010 |

Applications

Mine hoisting, blast furnace hoisting, large casting, oil drilling, forestry and marine industries,all kinds ofelevator, large hoisting, ground cable car ships and offshore facilities, cable railing.

How To Choose Material

1.stainless steel :

providing good corrosion resistance and strength comparable to galvanized carbon steel grades.

2.galvanized steel:

providing good corrosion resistance and strength comparable to galvanized carbon steel grades.

2.galvanized steel:

Zinc coated carbon steel offers some corrosion resistance. It remains ductile over long periods of working. Usually higher break strengths than stainless steels.

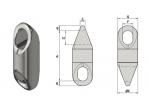

Packaging

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com