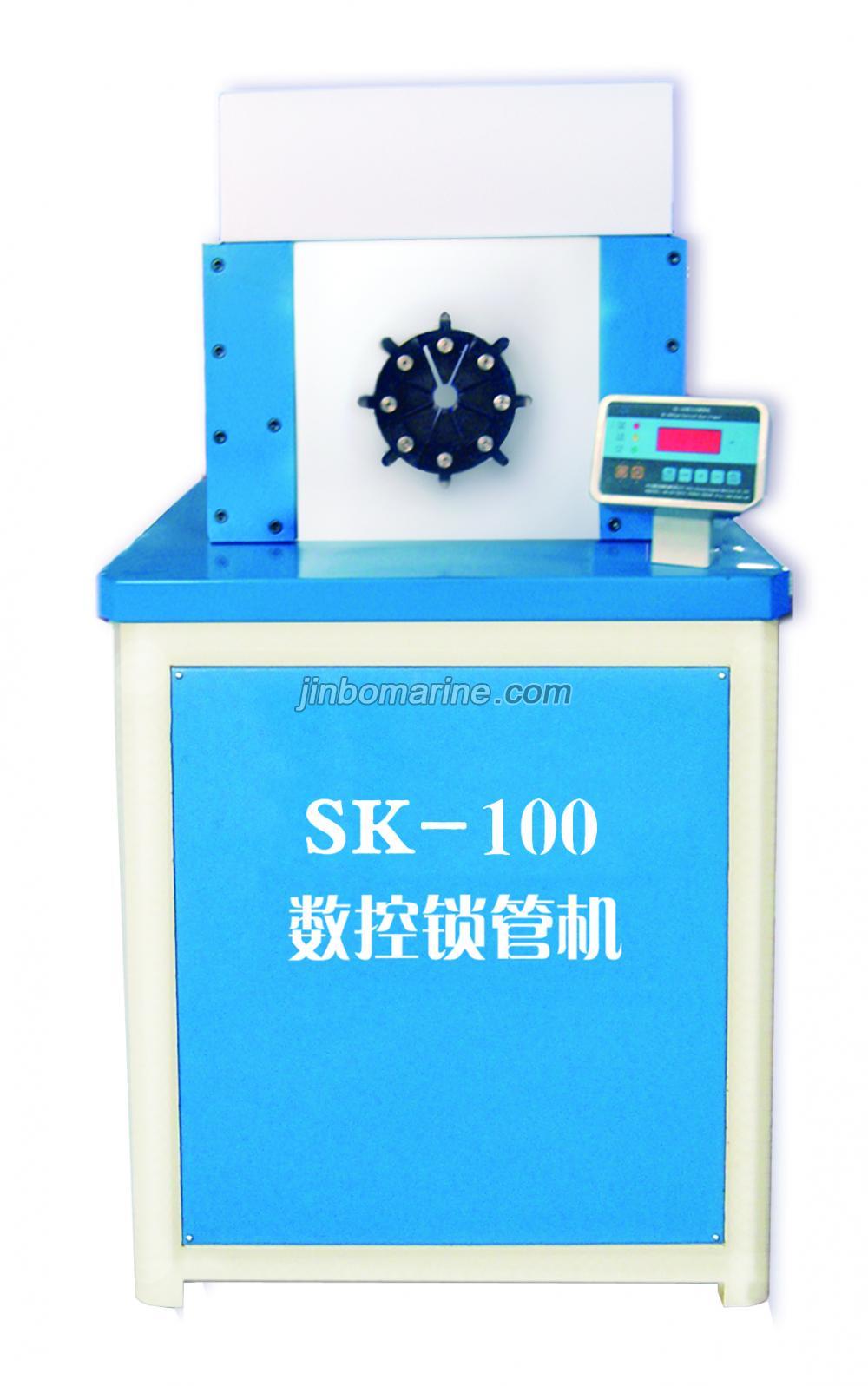

SK100 Numeric Control Locking Pipe Machine

- Category:Hose Crimping Machine

- Fob Price:Get Latest Price Now

- Place of Origin:China

Details

Main technical character

Hooping steel wire rubber tube inner diameter:φ4~φ51IVmm

Industry tube inner diameter:89mmat the most

Scale precision:0.01mm

Power:4KW

Voltage:380V

The maximum hooping force:252 tons

Rotated speed:1440r/min

Oil pump displacement:10ml/rad

Dimension:858×910×1550(mm)

Weight:800Kg

The maximum opening diameter:+68mm

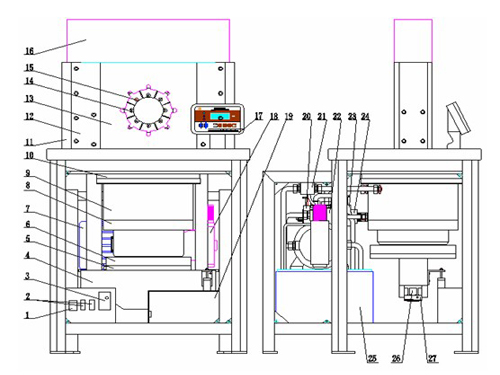

SK-100 type numerical control tube locking machine structure diagram:

1.bridge rectifier 2. relay 3. time delay unit 4. pressure bar 5. down jointbar 6. joint buckle closure 7. electric motor 8. down end closure 9. hydro-cylinder 10. up jointbar 11. slide board 12. clamping plate 13. back plate 14. die holder 15. drawbar 16. up covering cap 17. electrical equipment controlbox18. oil pump 19. electrical equipmentbox20. hooping pressure regulating valve 21. fluid control non-return valve 22. integrated circuit block 23. mould opening pressure regulating valve 24. magnetic change valve 25. oilbox26. nut 27. lock circular nut

|

Name: |

Hose crimping machine,hose crimper,Pipe locking machine,Locking pipe machine,tube |

|

Usage |

Crimping hose |

|

Popular |

DX68 Hydraulic high pressure hose crimping machine 6-51mm |

|

DSG51AMulti-function pipe crimping machine 6-51mm |

|

|

DSG51B Multi-function pipe crimper 6-51mm |

|

|

DSG75 High pressure hose crimper6-75mm |

|

|

DSG150 High pressure hose crimping machine 6-150mm |

|

|

DSG102S hose crimping machine 6-102mm |

|

|

DSG250A Locking Pipe Machine 6-51mm |

|

|

DSG250B tube crimping Machine 6-51mm |

|

|

DSG250C Pipe Locking Machine 6-51mm |

|

|

JK400 tube crimper 6-64mm |

|

|

JKS200 Manual type hose crimping machine 6-32mm |

|

|

SK100 Numeric control locking pipe machine 4-89mmSK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc.SK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc.SK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc.SK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc.SK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc.SK100Numeric control locking pipe machinedeveloped by our factory is suitable for hooping processing of the assembly of high pressure rubber tube, fibre pipe and plastic pipe used in industry,agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation,easy operation and maintenance, etc. |

Tel: 86-23-68428875,68428422,68838417

Fax: 86-4008266163-88928

Email: sales@jinbomarine.com